July 29, 2024 in Advisory Notes

Operational Analytics and Data Driven Maintenance (DDM)

Over the past decade, automated data analytics have been seamlessly integrated into various facets of our daily lives, including the operation and mai...

June 1, 2023

NABERS Rating and Commercial Drivers

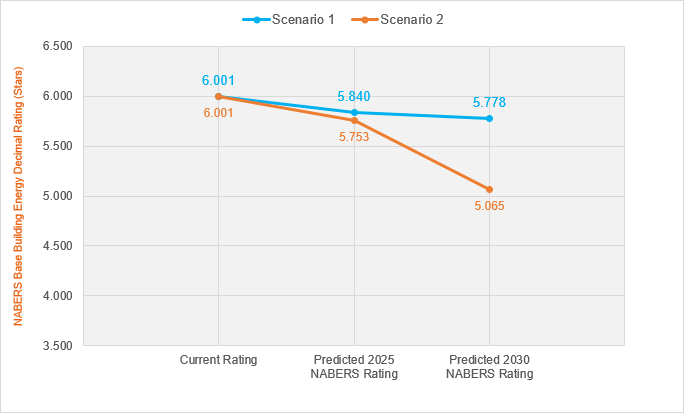

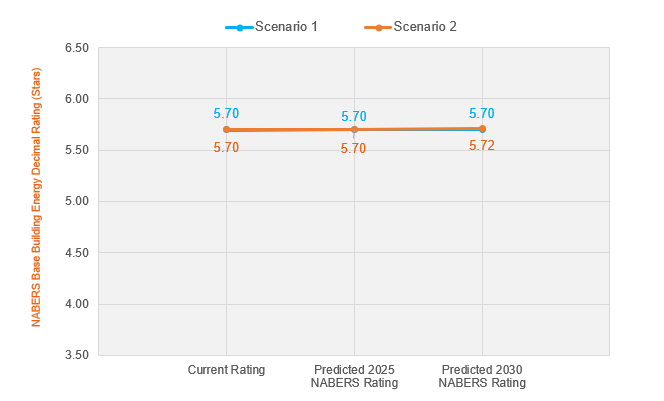

In 2021, NABERS updated the emissions factors used to represent the carbon intensity of grid electricity. Further updates are proposed in 2025 and 2030, to reflect the increase in renewable energy contributing to grid electricity. While the changes in 2021 were relatively modest, the next updates will have a much bigger impact on buildings that consume large amounts natural gas to meet their energy requirements, and this will particularly affect buildings that utilise trigeneration plants. The impact of the emissions factor changes can be seen below for two very similar, high-performing commercial buildings in Queensland, one with a trigeneration plant (which has been operating reliably) and another that sources almost all of its energy from grid electricity. Scenario 1 is based on the forecasted electricity grid emission factors predicted by the Australian Government. Scenario 2 assumed that by 2030, the grid will have decarbonised at a rate twice as fast as Scenario 1.

.

.

.

The result is that these plants will provide a reduced benefit to the NABERS Energy ratings and in some cases, particularly by 2030, they will have a negative impact on the energy rating.

The real cost of operating and maintaining a Trigeneration or cogeneration plant is now rarely justified by achieved benefits. On top of the expense of installing and commissioning the plant, the operating costs far outweigh the reduction in retail electricity and thermal energy savings. This is particularly true in Queensland and New South Wales, where complex emissions treatment systems are required. In particular, the reactive costs associated with breakdowns can catch building owners off guard – often requiring several different specialist contractors to diagnose and resolve the problem. This is all before the engine manufacturer’s scheduled rebuild is considered, which can cost upward of $300k.

Decommissioning

The main challenges in decommissioning trigeneration and cogeneration systems arise because they integrate with many other building systems. The natural gas generators often also provide standby power, and the supervisory controls include a number of safety interlocks to facilitate remote switching of Main Switch Board circuit breakers (an important function during switchboard maintenance). Reclaimed thermal energy contributes to the overall heating and cooling capacity of the central plant, satisfying peak demand requirements and sometimes Property Council of Australia Building Quality Matrix redundancy provisions. The other factor is that these systems are often buried in the heart of buildings or in rooftop plantrooms, making them extremely difficult to remove in one piece. Generators and absorption chillers are often upwards of 13 Tonnes, making cranage a logistical challenge.

.

Standby Power Considerations

Natural gas-fired generators are not well suited to standby power applications, particularly when operating at low or highly variable loads. Their load step capabilities are also limited and the additional gas-safety measures can impact the reliability of the plant during an outage. Diesel generators are better suited to standby power applications and can operate reliably and across a much wider range, handling much greater load steps. When decommissioning a trigeneration plant, an important consideration is whether to continue utilising the gas generator for standby power mode or if a diesel generator set is better suited.

Thermal Energy Considerations

Many heating hot water systems are designed with a temperature range upward of 60 degrees. This isn’t a problem for natural gas-fired generators, which circulate water at around 80-90 degrees through their cooling jackets. Gas-fired heating hot water generators/boilers are also able to operate at these temperatures. As buildings de-gasify and switch to electric power for heating however, it can be energy intensive and expensive to reach these temperatures using electric heat pumps. This can be a big problem for Air Handling Units that have coils designed to use heating hot water above 60 degrees. The impact of reducing the maximum heating hot water temperature from 80-60 degrees to 60-40 degrees can be a 1/3rd reduction in heating capacity through the AHU coils. There also needs to be consideration of the plant space required to accommodate heat pumps, which is often greater that an equivalent capacity gas-fired solution.

For chilled water produced through absorption chillers, the biggest impact is typically associated with a reduction to total chilled water capacity, which can fall below what is required to achieve the Property Council of Australia Building Quality Matrix Premium or A-Grade requirements for redundancy.

Electrical Capacity

Buildings that utilise trigeneration or cogeneration plants should have electrical infrastructure suitable with or without the operation of the generators. However, when sources of heat and cooling are ‘electrified’ (e.g. hundreds of KW of electric heat pumps), there are often limits on what can be achieved without major upgrades to the electrical infrastructure.

Looking forward

Every trigeneration or cogeneration system is different and needs to be assessed on a case by case basis. This should be done holistically, including consideration of other gas fired appliances such as HHW and DHW heaters or the addition of EV charging infrastructure. Carrying out a trigeneration feasibility study and carbon roadmap can help building owners understand the trigeneration plant’s contribution to the NABERs rating and plan a pathway back to meet or exceed their previous NABERs rating, or chart a course to net zero.

Importantly for building owners and facility managers, decommissioning these complex systems can simplify the operation of their building, reduce operating expenses and improve reliability. However, it is important to remember that removal of these systems is likely to have a short-medium term impact on the NABERs Energy rating (until the emissions factors are updated).

This reduced operating expense can provide a opportunity to reclaim some ground and focus on other energy efficiency opportunities within the building. Initiatives such as building tuning and new high efficiency chillers and hot water heaters can lead to net improvements in a building’s emissions intensity and help facilitate a transition to net zero.

For more information about Carbon Roadmap, visit:

www.agcoombs.com.au/a-g-coombs-carbon-roadmap

|

For more information about EV charging in buildings, contact: |

|

John Bourne – A.G. Coombs Advisory P: +61 7 3648 0500 E: jbourne@agcoombs.com.au |

July 29, 2024 in Advisory Notes

Over the past decade, automated data analytics have been seamlessly integrated into various facets of our daily lives, including the operation and mai...

June 24, 2024 in Advisory Notes

Mould plays an important role in the natural environment as a break-down mechanism for dead organic matter. In the built environment, it is an unwante...

April 30, 2024 in Advisory Notes

A lot has changed since A.G. Coombs released our first Advisory Note on heat pumps back in 2018. Increasingly, asset owners are no longer asking if he...

March 12, 2024 in Advisory Notes

Building owners and facility managers often don’t have access to a full set of accurate documentation for of their buildings to support effective an...